- As India pushes itself forward for local electronics manufacturing, from semiconductor fabs to the Electronics Component Manufacturing Scheme (ECMS), e-waste recycling threatens to undercut the progress.

About e-Waste in India

- E-waste — discarded electronic and electrical equipment — contains valuable materials such as copper, aluminum, nickel, cobalt, lithium, gold, and rare earth elements (REEs).

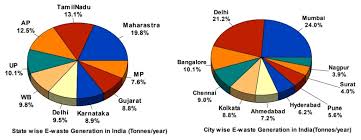

- India generated an estimated 4.17 million metric tonnes of e-waste in 2022, but only about one-third of this was processed through formal channels.

- It is driven by increased use of electronics, rapid obsolescence, and consumer upgrades.

- According to TRAI, India has over 93.9 crore mobile broadband connections, but accounts for only about 4% of global electronics consumption.

________________________________________________________________________

Gaps in Collection and Recycling

- A 2023 report by the Indian Cellular and Electronics Association highlights that e-waste recycling is largely dominated by the informal sector, which handles up to 90–95% of e-waste using unsafe methods such as open burning and acid leaching.

- Key Challenges:

- Low formal collection (less than 10%) and recycling rates;

- Health hazards for informal workers exposed to toxic substances;

- Traceability issues in recovered materials, leading to leakage back into informal streams;

- Fake reporting and malpractices in the EPR system — such as ‘paper trading’ of recycling credits — have raised concerns over credibility.

- Lack of standardized inventory systems and third-party audits.

Policy and Industry Response

- E-Waste (Management) Rules, 2022: These rules aim to ensure environmentally sound management of e-waste, and strengthen the Extended Producer Responsibility (EPR) regime, requiring manufacturers, producers, refurbishers, and recyclers to register on the CPCB portal. Key provisions include:

- Environmental compensation for violations;

- Verification and audit mechanisms;

- Circular economy promotion through scientific recycling.

- Formal Recycling Infrastructure (February 2025): India has 322 registered recyclers with a processing capacity of over 22 lakh metric tonnes per year.

- 72 registered refurbishers with a capacity of 92,000 metric tonnes per year.

- Public Awareness and Education: MeitY, in collaboration with industry bodies like MAIT and NASSCOM, has launched awareness campaigns across 31 states/UTs.

- Innovative models like ‘mandi-style’ aggregation systems are being piloted to link informal collectors with formal recyclers.

________________________________________________________________________

Road Ahead

- Scaling up formal operations;

- Curbing malpractices in the EPR system;

- Enhancing product life cycles through repair;

- Creating robust inventory systems;

NOTE – This article was originally published in NEXTIAS and can be viewed here

Tags: #conditioners, #electric, #environment, #ewaste, #getgreengetgrowing, #gngagritech, #greenstories, #humanhealth, #materials, #recycling, #refrigerators, #televisions